Our Financial Accountant, Bevis Muller is perhaps the most humble and self-deprecating man you could ever meet. When told he was going to be our featured employee for our website, he said there are probably far more interesting people to write about. But this is actually far from the case, read on to find out more…

In the world of finance, where numbers rule and precision is paramount, Bevis Muller stands out as a unique and fascinating individual. At 55 years of age and with a wealth of experience under his belt, Bevis’s journey has been far from ordinary.

Early Years in Zimbabwe: A Life Marked by Turmoil and Resilience

Born in 1968 in Mutare, Zimbabwe (then known as Umtali, Rhodesia), Bevis spent his early years in a tiny town on the border between Zimbabwe and Mozambique. It was a tumultuous time, marked by mortar attacks during the independence war from 1975 to 1980. As a young boy, Bevis and his family would take shelter in the passages, away from the windows, seeking safety amid the chaos.

Growing up, Bevis was greatly influenced by his father, a school teacher who he says embodied true Christian values. “He lived a life of great integrity, and gave his opinion only if you asked him,” says Bevis. His father’s unwavering faith left a lasting impression on Bevis and it was his father’s example that instilled in him the importance of humility and honesty.

From Rebellious Teenager to a Life-Altering Wake-Up Call

“Although I grew up in a loving, Christian home, I was a loud-mouthed, rebellious teenager,” he confesses. “At 17, I rolled my friend’s car three times, racing another car in Harare. It was completely dangerous and reckless.” Miraculously, Bevis was thrown out of the car and emerged unharmed, while his friend ended up in hospital. This life-altering experience helped to redirect his path. “I was careless as a teenager and I think the car incident served as a bit of a wake-up call,” says Bevis, reflecting on what could have been. “The incident helped to sober my rebellious streak, and shortly after that I became a Christian.”

Fast-forward a few years and Bevis began his professional path, qualifying as a Chartered Accountant in 1992. “It wasn’t a straightforward office job,” he says. “I was often sent to do audits in Mozambique; for example of the main fuel pipeline from Beira to Mutare.” However, due to the ongoing civil war, they had to drive across Mozambique with an armed escort sitting on the back of the ute! While that was a rather extreme way to get to work, he says the audit partner, of course, would refuse to risk travel by car. “He would instead fly in on a chartered plane!”

Auditing Amidst Civil War and Economic Instability

Bevis then worked as a Finance Manager for a steel trading division before rising to the position of Group Financial Controller. His expertise and dedication were recognised, but it was the economic instability in Zimbabwe that ultimately drove Bevis to emigrate. “Although I had a good job, by the time we left in December 2007, the inflation rate was well over 1000% per annum – more than 100% per month,” he recalls. “We had daily power cuts and water outages, and the unemployment rate was measured at 86%, so crime rates were inevitably on the rise, through sheer desperation.”

To give an idea of the worsening economy, in 2005 Bevis and his wife Gabby borrowed Z$600 million to buy a house (1.5 acres, including a cottage for his parents). “Within 18 months of the loan,” he says, “I could have repaid it with a single bank note from my wallet.”

But while inflation erased their debt, at the same time it exponentially destroyed people’s savings and pension balances. “I believe the highest bank note ever recorded was the Z$100 trillion note!” he says.

Bevis’s older sister now lives in the UK, after her family had to leave their farm when it was invaded by Mr Mugabe’s war veterans. His younger brother still lives in Zimbabwe. He stayed there after their parents died; his Shona (the local dialect) is as good as his English.

A Life-Changing Move to Perth: From Hardships to a New Start

In 2007, Bevis and his family made the life-changing move to Perth, leaving behind the hardships of Southern Africa. Despite starting his first job for a transport company in a windowless container, Bevis found joy in being near the ocean. “I could not believe how beautiful and clean the city of Perth was when we arrived. We had jumped from one of the bottom ten cities in the world to one of the top ten. We felt truly blessed.”

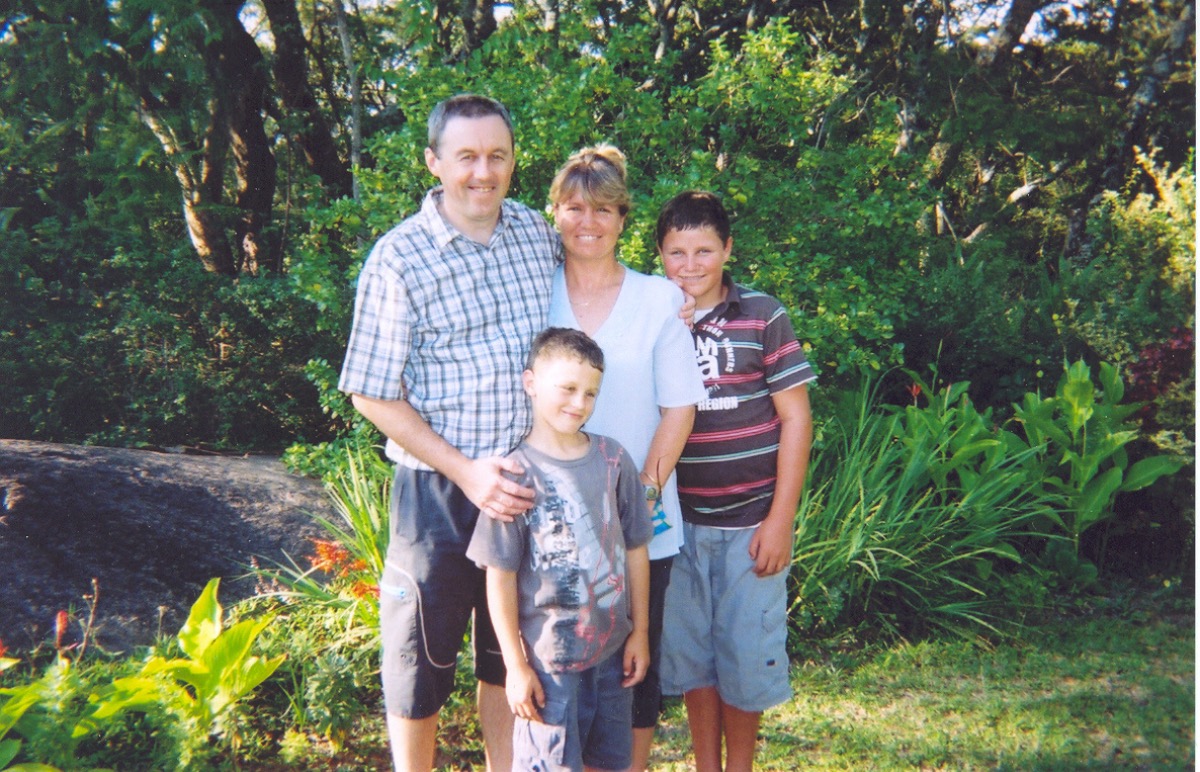

Bevis says his life is enriched by his family. His wife has been by his side for over three decades, supporting him through thick and thin. Together, they have two sons, Matt (28) and Luke (24), and a grandson named Ezekiel (3). In 1997, the couple tragically lost their second son a day after he was born. A year later, Gabby gave birth to Luke, bringing new hope.

However, tragedy almost struck a second time. The family were visiting a neighbour’s house one day, and Luke, then four, was playing with the other children in the garden. The neighbour had recently installed a swimming pool, and as they were still filling it, the shallow end was dry and the deep end was only partially filled. Bevis recalled, “I went outside to check on them and found Luke lying on the bottom of the pool, looking up. It was horrifying,” he says. “By God’s grace, it must have just happened that exact minute as I pulled him out and he was shaken, but fine.” Understandably, the ordeal profoundly shaped Bevis as a person. “I think it has made me very protective of my sons, and now of my grandson.”

His life story is a reminder that amidst the numbers and spreadsheets, there is a human being with a rich tapestry of experiences and a strong love for his family. “My favourite place to be is wherever my grandson is! I love to be around my family, and Margaret River is one of my favourite places to holiday.”